The Explosion-proof Moisture Barrier Vent is a high-performance safety component designed to provide effective pressure relief while preventing moisture, dust, and contaminants from entering sealed enclosures. As an advanced Explosion Proof Vent, this solution is engineered for environments where flammable gases, pressure fluctuations, and high humidity coexist, ensuring both operational safety and long-term equipment reliability.

By combining explosion resistance, moisture protection, and controlled airflow, this Moisture Barrier Vent plays a critical role in safeguarding sensitive electronic and mechanical systems across demanding industrial applications.

Technical Specifications

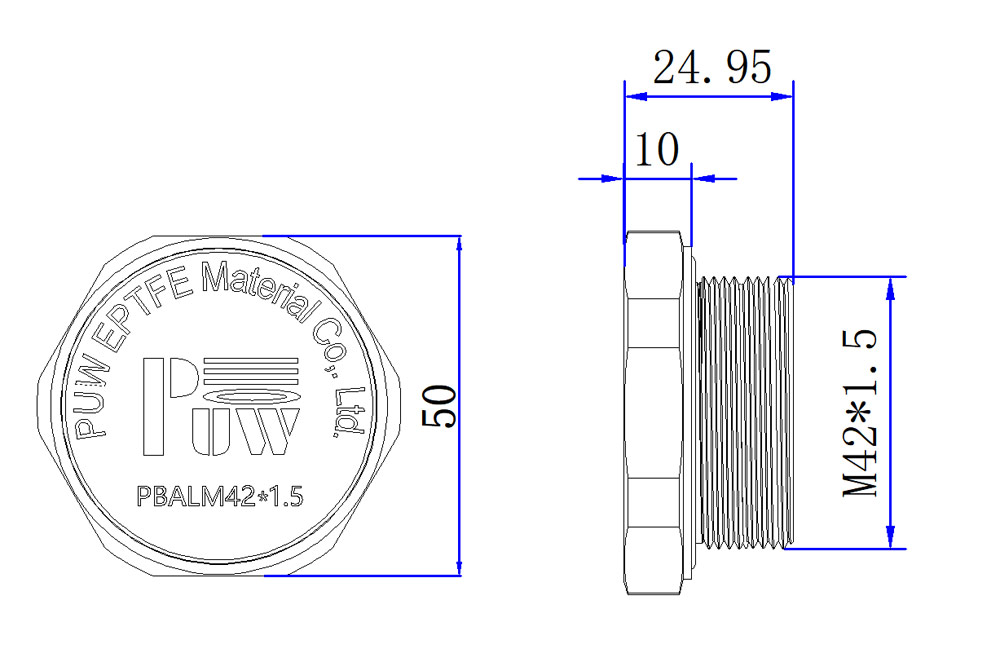

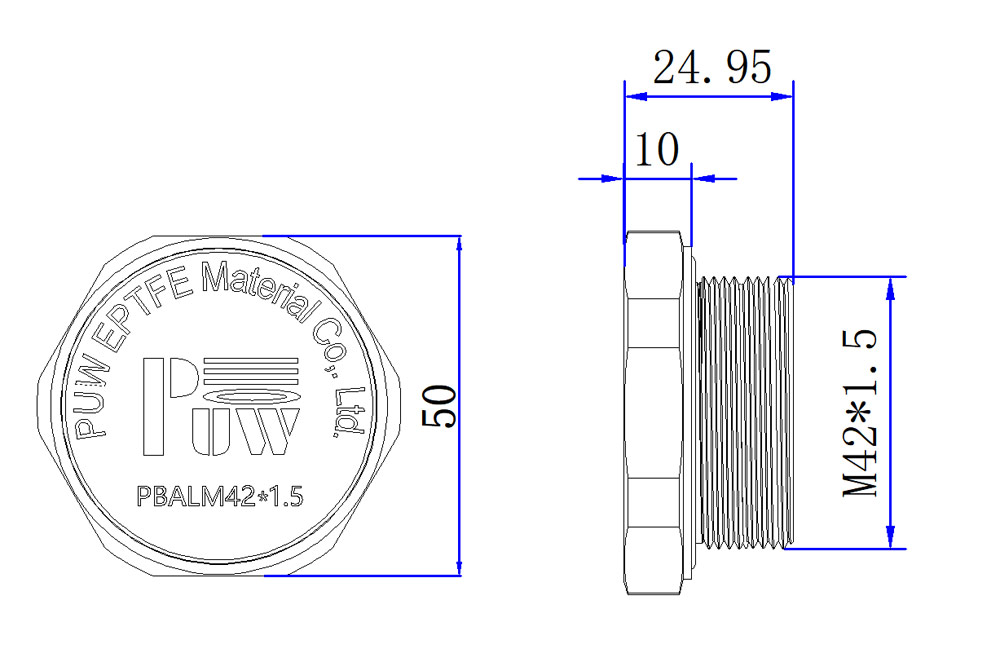

| Product model | PB10ALM42*1.5-10P-8T |

|

|

| Product type | Waterproof, breathable and explosion-proof valves | Body Material | Aluminum alloy |

| Valve installation type | Exterior flange type(moisture barrier type) | Ingress protection | IP68/6K9K |

| Air permeability ML/min@1.5kPa | Air intake ≥ 9

the gas output ≥ 50 | kPa Turning pressure kPa | 7~13 |

| Air permeability ML/min@2.5kPa | Air intake ≥ 15

the gas output ≥ 600 | Installation: | Threaded mounting |

| Fully open exhaust area of the spool (mm²) | 590 |

|

|

Advanced Explosion Protection and Moisture Control

At its core, the Explosion-proof Moisture Barrier Vent functions as a Protective Vent that safely releases internal pressure without allowing external moisture or debris to penetrate the enclosure. Its explosion-proof structure ensures that vented gases are discharged in a controlled manner, significantly reducing the risk of ignition in hazardous atmospheres.

As a Moisture-proof Pressure Vent, it effectively blocks liquid water and water vapor, helping to prevent condensation-related failures such as corrosion, short circuits, and insulation degradation. This dual-protection design makes it ideal for applications requiring strict explosion safety and environmental sealing.

Designed as a Waterproof Breathable Vent, the valve allows air and gas molecules to pass through while maintaining a robust waterproof barrier. This breathable functionality supports rapid pressure equalization during temperature changes, altitude variation, or internal gas generation.

As a dedicated Pressure Equalization Vent, it helps maintain internal pressure balance, protecting enclosures from deformation, seal damage, or structural failure caused by pressure build-up or vacuum conditions.

High-Performance ePTFE Vent Membrane Technology

The vent integrates a high-quality ePTFE Vent Membrane, also known as a PTFE Breathable Membrane, which is the key element enabling both breathability and moisture resistance. The microporous PTFE structure provides:

Excellent air permeability

Strong hydrophobic and oleophobic properties

High chemical resistance

Long-term stability in harsh environments

This membrane technology ensures reliable performance even under continuous exposure to humidity, chemicals, dust, and fluctuating pressures.

Explosion Resistant Vent Plug with Durable Construction

As an Explosion Resistant Vent Plug, the valve features a robust aluminum alloy body that offers an optimal balance of strength, corrosion resistance, and lightweight design. The exterior flange structure and threaded mounting ensure a secure, leak-proof installation on various enclosure types.

The valve’s high ingress protection rating enables it to function as a Waterproof Explosion-proof Vent, maintaining reliable sealing performance under dust exposure, high-pressure water jets, or temporary immersion.

High Airflow Capacity and Controlled Venting Performance

This Breathable Explosion-proof Valve is engineered to deliver excellent airflow performance, enabling fast and safe pressure release when needed. Its carefully calibrated opening pressure ensures that venting occurs only when internal pressure reaches a defined threshold, protecting enclosures without compromising sealing integrity.

By combining high airflow output with precise pressure control, the valve minimizes stress on enclosure structures and internal components.

Typical Applications

Thanks to its combination of explosion resistance, moisture protection, and pressure regulation, the Explosion-proof Moisture Barrier Vent is widely used in:

Oil and gas equipment enclosures

Chemical processing plants

Mining control cabinets

Outdoor electrical junction boxes

Battery storage and energy systems

Marine and offshore equipment housings

Industrial automation and control systems

In all these applications, the vent acts as a reliable Protective Vent that enhances safety, durability, and operational stability.

Key Advantages at a Glance

Dual Functionality: Explosion-proof protection combined with effective moisture barrier

Reliable Pressure Equalization: Prevents enclosure deformation and seal failure

Advanced Membrane Technology: High-performance ePTFE / PTFE breathable membrane

Waterproof & Dustproof: Suitable for harsh outdoor and industrial environments

Durable Design: Aluminum alloy construction for long service life

Flexible Integration: Threaded installation for easy mounting

A Trusted Solution for Hazardous Enclosures

Whether used as an Explosion Proof Vent, Moisture Barrier Vent, or Waterproof Breathable Vent, this product delivers dependable protection in environments where safety and environmental sealing are non-negotiable. By integrating explosion resistance, pressure equalization, and moisture control into a single solution, it provides a smart and efficient way to protect critical equipment and extend service life.

Explosion-Proof Moisture Barrier Vent – FAQ

1. What is the primary function of the Explosion-Proof Moisture Barrier Vent?

This valve provides a safe and controlled way to release internal pressure from enclosures while preventing moisture, dust, and contaminants from entering. It also ensures explosion protection in hazardous environments.

2. In which industries is this vent commonly used?

It is widely used in mining, oil and gas, chemical processing, marine equipment, and outdoor electrical enclosures where explosion risks and moisture exposure coexist.

3. What is the valve’s ingress protection rating?

The vent has an IP68 / 6K9K rating, meaning it is fully dust-tight and can withstand powerful water jets and temporary submersion, making it suitable for harsh outdoor environments.

4. How does the moisture barrier work?

The moisture barrier design blocks water vapor and liquid moisture from entering the enclosure while allowing gases to safely vent out, protecting sensitive electronic and mechanical components.

5. What materials are used in the valve construction?

The valve body is made of durable aluminum alloy, providing corrosion resistance and strength suitable for industrial applications.

6. What are the airflow and pressure specifications?

Air intake permeability at 1.5 kPa: ≥ 9 ML/min

Gas output at 1.5 kPa: ≥ 50 ML/min

Air intake permeability at 2.5 kPa: ≥ 15 ML/min

Gas output at 2.5 kPa: ≥ 600 ML/min

Opening pressure range: 7 to 13 kPa

7. How is the valve installed?

It features an exterior flange type with threaded mounting for easy and secure installation on enclosure surfaces.

8. Can this valve withstand extreme temperatures?

Yes, it is designed for demanding industrial environments and can operate reliably across a broad temperature range (please consult specific datasheets for exact temperature limits).

9. Does this vent require maintenance?

The valve is designed for long-term use with minimal maintenance. However, periodic inspections are recommended to ensure no clogging or damage occurs, especially in harsh environments.

10. Can the valve be customized?

Yes, OEM and ODM services are available to tailor the valve’s size, material, and performance specifications to your project requirements.