Focus on PUW EPTFE Material Co., Ltd - Get to know the new information of the industry quickly!

2025-08-20 18:00:38

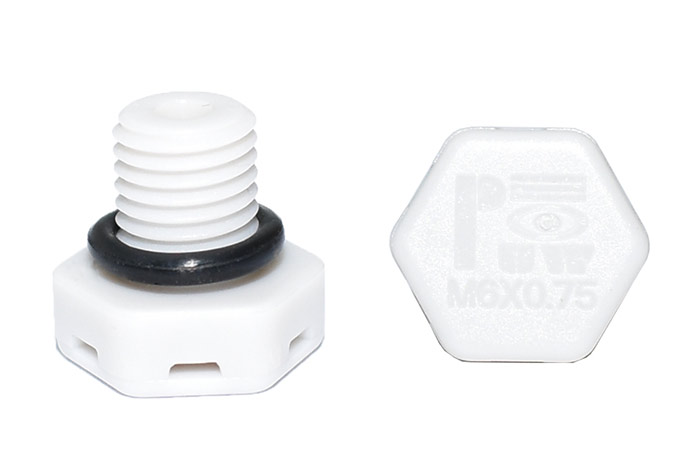

In modern industrial and mechanical systems, Plastic Breather Valves play a crucial role in ensuring proper ventilation, pressure balance, and protection against contaminants. Selecting the right breather valve for your machinery can significantly impact performance, reduce maintenance costs, and extend equipment lifespan. With the advancement of Waterproof Breathable Valve technology, machinery operators can now enjoy enhanced protection from water ingress while maintaining proper ventilation.

Understanding Plastic Breather Valves

A plastic breather valve is a type of ventilation device typically installed on hydraulic systems, gearboxes, fuel tanks, and other enclosed machinery. Its primary function is to allow air to enter and exit the system safely while preventing dirt, dust, and other contaminants from entering.

Unlike metal valves, plastic breather valves are lightweight, corrosion-resistant, and suitable for environments where chemical resistance is critical. They also reduce the risk of galvanic corrosion, making them ideal for a wide range of industrial and mechanical applications.

Why Choosing the Right Breather Valve Matters

Maintaining Pressure Balance

Incorrect or inadequate breather valves can cause pressure imbalances inside tanks and gearboxes, leading to seal failures, leaks, or operational inefficiencies. A properly selected plastic breather valve ensures consistent internal pressure, protecting sensitive components.

Preventing Contamination

A high-quality plastic breather valve filters out dust, moisture, and airborne particles, preventing contamination of lubricants, fuels, and hydraulic fluids. Advanced Waterproof Breathable Valve designs also prevent water from entering the system during rain, cleaning, or high-humidity environments.

Enhancing Equipment Lifespan

Machinery components exposed to unfiltered air or excessive pressure are prone to wear and corrosion. Using the right breather valve reduces these risks, leading to longer-lasting equipment and fewer unexpected downtimes.

Optimizing System Efficiency

By allowing controlled airflow, plastic breather valves prevent vacuum or pressure buildup that can affect pumps, hydraulic systems, and fluid circulation. This ensures smooth operation and energy efficiency across machinery.

When selecting a plastic breather valve, consider the following factors:

Material Quality: High-grade plastics resistant to chemicals, UV exposure, and extreme temperatures.

Filtration Efficiency: Fine mesh or filter elements to prevent ingress of dust and particles.

Flow Capacity: Adequate airflow rating to handle the system’s volume and pressure fluctuations.

Waterproof & Breathable Design: Advanced Waterproof Breathable Valve options allow air passage while blocking water.

Ease of Installation: Compact design with standard fittings or threads for quick and secure installation.

Durability: Resistance to cracking, wear, and environmental stress for long-term performance.

Hydraulic Systems

Maintains system pressure, prevents contamination, and protects pumps and cylinders.

Gearboxes & Transmission Units

Prevents vacuum build-up, reduces seal wear, and ensures smooth mechanical operation.

Fuel & Storage Tanks

Allows safe air exchange while preventing dirt, moisture, and water ingress with Waterproof Breathable Valve options.

Industrial Equipment

Used in compressors, generators, and heavy machinery to maintain ventilation and protect internal fluids.

Automotive & Marine Applications

Plastic breather valves provide corrosion resistance and moisture protection for engines, fuel systems, and enclosed compartments.

Corrosion Resistance: Plastic construction prevents rust and chemical degradation.

Lightweight & Easy Handling: Simplifies installation and maintenance.

Cost-Effective: Lower production and replacement costs compared to metal valves.

Environmental Resistance: Effective in harsh weather, high humidity, and chemical-exposed environments.

Enhanced Safety: Reduces the risk of seal failure, leaks, or system damage caused by pressure imbalances.

Compatibility with Waterproof Solutions: Modern Waterproof Breathable Valve designs offer protection in outdoor and wet conditions without sacrificing airflow.

Regular Cleaning: Periodically remove accumulated dust or debris from the filter element.

Inspection: Check for cracks, wear, or clogging to ensure proper airflow.

Replacement: Replace the valve if damaged or if airflow is restricted.

Correct Sizing: Always match the valve to the machinery’s volume and pressure requirements for optimal performance.

Q1: What is the difference between a plastic breather valve and a metal one?

A: Plastic breather valves are corrosion-resistant, lightweight, and suitable for chemically aggressive environments, while metal valves offer higher mechanical strength but can corrode.

Q2: Can a plastic breather valve be used outdoors?

A: Yes, especially if it is a Waterproof Breathable Valve, which prevents water ingress while allowing air circulation.

Q3: How do I know which size or flow capacity I need?

A: Check the system’s air exchange volume and pressure fluctuations. The valve should accommodate peak airflow without creating vacuum or pressure issues.

Q4: Are these valves reusable?

A: Most plastic breather valves can be cleaned and reused, but the filter element should be checked regularly and replaced if clogged.

Q5: Can they be installed on hydraulic and fuel systems simultaneously?

A: Yes, but ensure the material is compatible with the fluid type, temperature, and environmental conditions.

Selecting the right plastic breather valve is essential for protecting machinery, maintaining efficiency, and extending equipment life. With advancements in Waterproof Breathable Valve technology, operators can now enjoy airflow management while preventing water ingress, ensuring optimal performance in harsh or outdoor conditions. Proper selection, installation, and maintenance of these valves lead to safer, more reliable, and cost-effective machinery operation across multiple industries.

Telephone: 0769-22850556

Email: lvch@puw-eptfe.com

Address: No.20, Wanjiang Industrial Street, Wanjiang District, Dongguan City, Guangdong Province, China

© 2026 PUW EPTFE Material Co., Ltd. All rights reserved.

Privacy policy | Terms and Conditions