Focus on PUW EPTFE Material Co., Ltd - Get to know the new information of the industry quickly!

2025-09-22 15:55:27

In modern electronics and industrial devices, Waterproof Breathable Vents have become essential components to protect sensitive equipment from moisture, dust, and environmental damage. Among various materials, EPTFE vent technology stands out for its superior performance in waterproof vent and breathable vent applications.

Expanded PTFE (ePTFE) membranes are microporous materials derived from polytetrafluoroethylene (PTFE). The expansion process creates a network of tiny pores, typically in the range of 0.1 to 5 microns. These pores are large enough to allow air and vapor to pass through but small enough to block liquid water.

This unique structure is the core reason why PTFE venting membranes provide waterproof breathable vent functionality. The microporous network acts like a sieve for liquids, while still allowing breathable vents to equalize pressure inside enclosures.

Water Resistance:

The hydrophobic nature of PTFE prevents water penetration. Even under pressure, the tiny micropores stop liquid water from entering, making it suitable for IP-rated applications, such as IP67 vent designs.

Air and Vapor Permeability:

The pores allow water vapor and air to pass through, preventing condensation inside the device. This is critical for electronics, medical equipment, and industrial devices that operate in varying temperature environments.

Pressure Equalization:

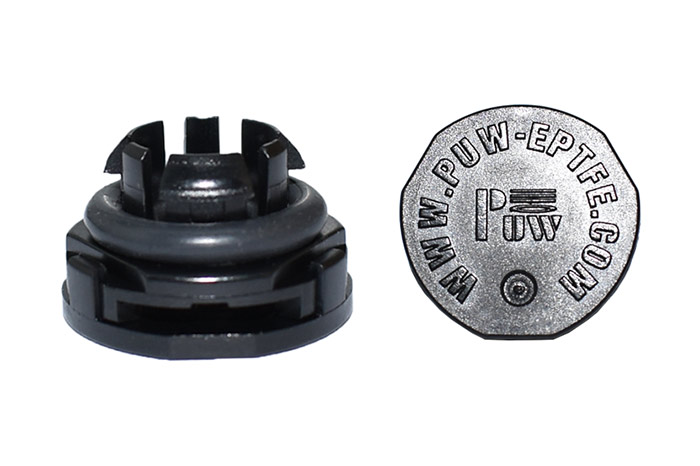

Devices like sensors, enclosures, and battery boxes can experience pressure changes due to temperature fluctuations. Plastic breather valves integrated with ptfe venting membrane ensure smooth pressure balance without compromising waterproof protection.

Durability and Chemical Resistance:

EPTFE Membranes are chemically inert, UV-resistant, and withstand a wide range of temperatures, making them ideal for outdoor and harsh industrial environments.

Electronics and Enclosures: Protecting cameras, sensors, and control units while allowing airflow.

Automotive and Aerospace: Waterproof vents for headlamps, battery packs, and electronic control modules.

Medical Equipment: Maintaining sterility while allowing pressure equalization.

Industrial Machinery: Venting systems in pumps, valves, and motor housings.

Outdoor Devices: Waterproof breathable vents for GPS units, wearable electronics, and protective cases.

Compared to traditional rubber or plastic venting solutions, ePTFE vent and PTFE venting membranes offer:

Superior waterproof breathable vent performance

Long-lasting chemical and UV resistance

Stable operation under high or low temperatures

Compatibility with plastic breather valve and enclosure designs

Easy integration into IP67 vent and other high-protection rated products

The microporous structure of ePTFE vent ensures that PTFE venting membranes provide a reliable waterproof vent solution while maintaining breathability. Whether it’s a plastic breather valve for industrial machinery or a waterproof breathable vent for outdoor electronics, ePTFE membranes deliver the ideal combination of durability, permeability, and protection.

By selecting high-quality ptfe venting membrane solutions, manufacturers can extend the lifespan of their devices, maintain performance in harsh environments, and meet stringent IP protection standards.

Telephone: 0769-22850556

Email: lvch@puw-eptfe.com

Address: No.20, Wanjiang Industrial Street, Wanjiang District, Dongguan City, Guangdong Province, China

© 2026 PUW EPTFE Material Co., Ltd. All rights reserved.

Privacy policy | Terms and Conditions