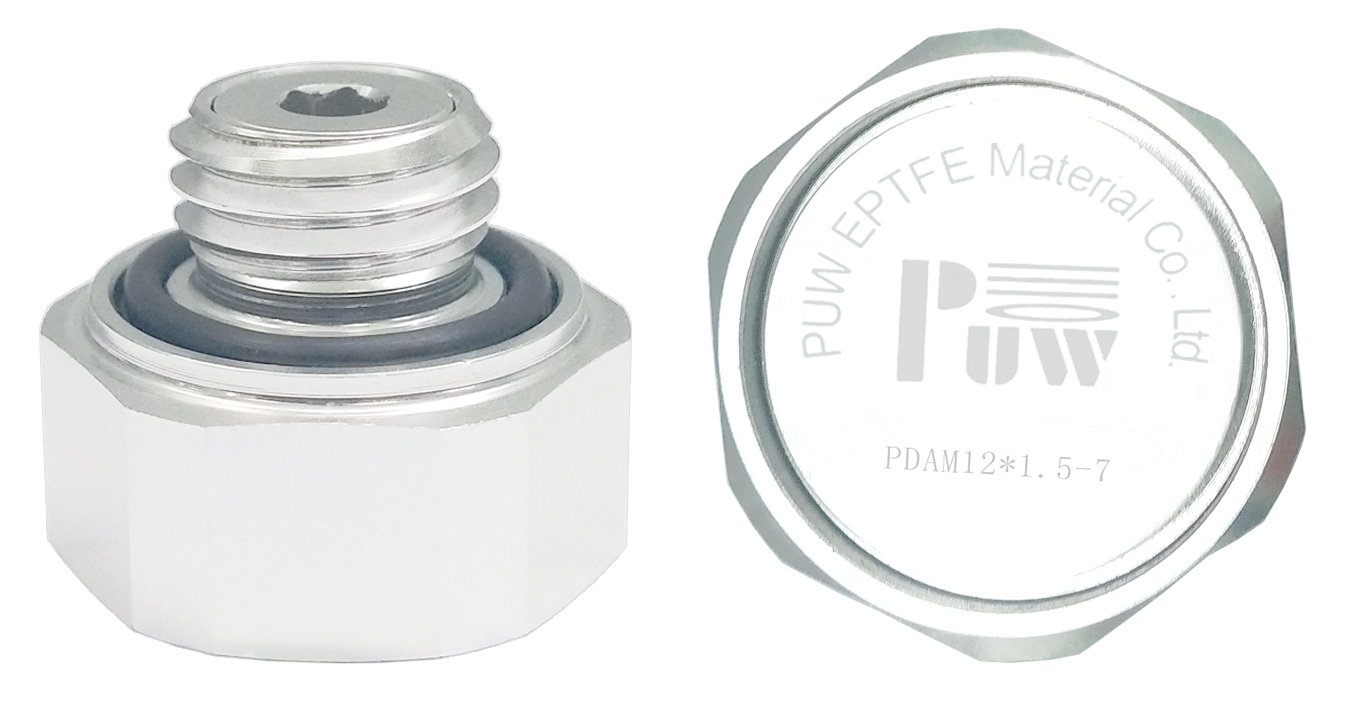

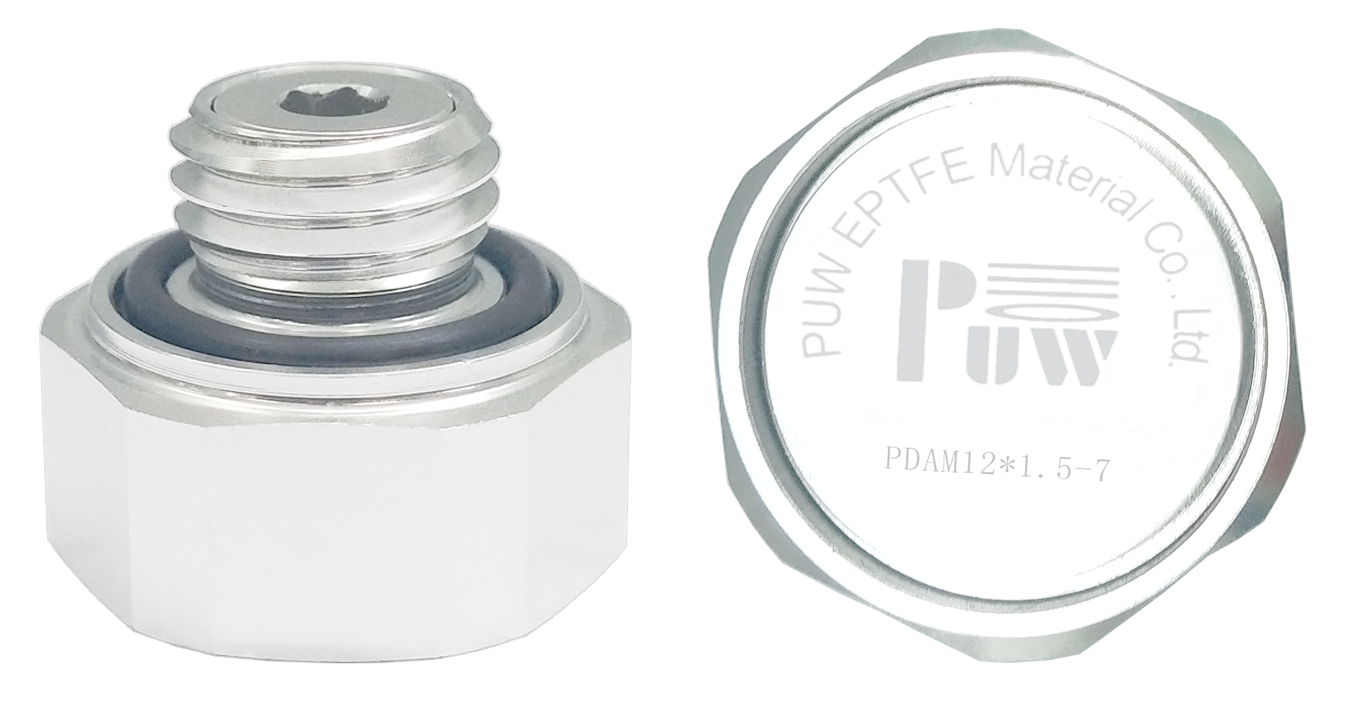

The Explosion Prevention Valve is an advanced solution designed to enhance safety in critical applications. Engineered with high-strength aluminum and coated with an anti-oxidation layer, it offers excellent durability and corrosion resistance. The valve features a high protection rating of IP68 or above, ensuring robust performance in harsh environments. It integrates dual channels for efficient ventilation and rapid pressure relief, maintaining optimal pressure balance. The explosion prevention point is highly customizable, allowing precise settings to meet specific customer requirements. The valve is backed by multiple patents and certified to international standards such as ISO and IATF16949. Its design ensures quick gas tightness detection and easy installation, making it a reliable choice for various industrial needs.

| Product model | PD10A4K-42 |

|

|

| Product type | Waterproof, breathable and explosion-proof valves | Body Material | Aluminum alloy |

| Valve installation type | Unidirectional explosion-proof valve (without waterproof and breathable membrane) | Ingress protection | IP68/6K9K |

| Air permeability ML/min@1.5kPa | / | kPa Turning pressure kPa | 7~13 |

| Air permeability ML/min@2.5kPa | / | Installation: | 4-hole external mounting |

| Fully open exhaust area of the spool (mm²) | 400 |

|

|

Rapid Pressure Relief: The valve automatically opens to release excess pressure during abnormal conditions, preventing catastrophic failure of equipment such as dust collectors, silos, and pneumatic systems.

Reliable Explosion Protection: Designed to withstand harsh industrial conditions, the valve effectively isolates and controls explosion flames and pressure waves, reducing the risk of secondary explosions.

Durable Construction: Made from high-quality materials such as stainless steel or aluminum alloys, the valve offers superior corrosion resistance, long service life, and excellent mechanical strength.

Versatile Applications: Suitable for use in chemical plants, grain processing, pharmaceuticals, mining, and other industries prone to dust or gas explosions.

Compliance and Certification: Our Explosion Prevention Valves meet stringent international safety standards, including ATEX and ISO certifications, ensuring reliable performance and regulatory compliance.

Benefits of Using Explosion Prevention Valves

Protects valuable equipment and infrastructure from explosion damage

Enhances workplace safety by controlling hazardous pressure conditions

Reduces downtime caused by explosion-related incidents

Facilitates compliance with safety regulations and insurance requirements

Easy to install and maintain, minimizing operational disruption

Typical Applications

Dust collection systems and filters

Pneumatic conveying lines

Storage silos and hoppers

Industrial dryers and ovens

Chemical reactors and processing units

Why Choose Our Explosion Prevention Valve?

Our explosion prevention valve is engineered with precision and backed by years of experience in industrial safety solutions. It integrates cutting-edge technology with durable materials to deliver superior explosion protection. Whether your operation involves combustible dust, flammable gases, or high-pressure environments, our valve provides a reliable safety barrier to protect your assets and personnel.

FAQ – Explosion Prevention Valve

Q1: What is an explosion prevention valve?

A1: It is a safety device designed to release excess pressure quickly during an explosion event to prevent equipment damage and ensure operator safety.

Q2: How does the explosion prevention valve work?

A2: The valve senses abnormal pressure buildup and opens automatically to vent pressure and flames, preventing secondary explosions.

Q3: What materials are used to make the valve?

A3: Common materials include stainless steel and aluminum alloys, chosen for their strength, durability, and corrosion resistance.

Q4: In which industries is this valve commonly used?

A4: It is widely used in chemical manufacturing, food processing, pharmaceuticals, mining, and any industry handling combustible dust or gases.

Q5: Does the valve comply with safety standards?

A5: Yes, our valves meet international certifications such as ATEX and ISO, ensuring they comply with global safety regulations.

Q6: Can the valve be customized for specific applications?

A6: Yes, we offer customization options based on pressure ratings, materials, and size to fit various industrial needs.