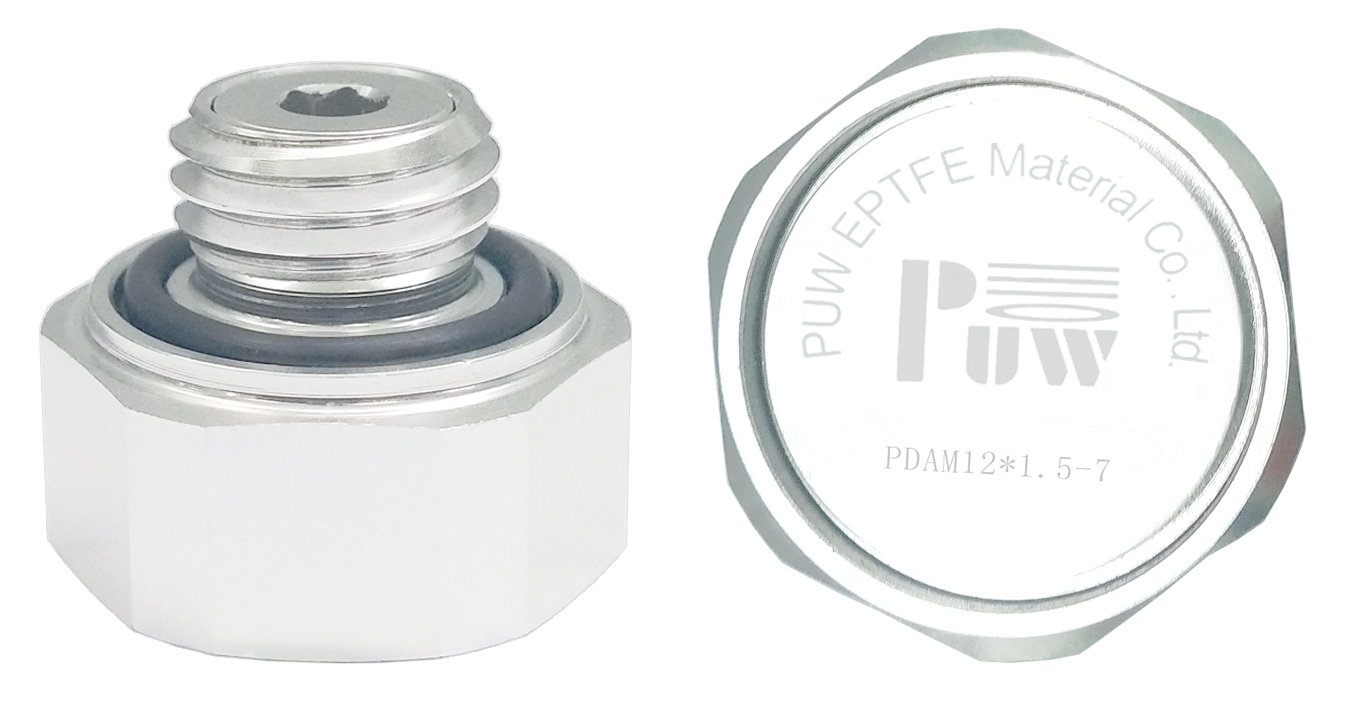

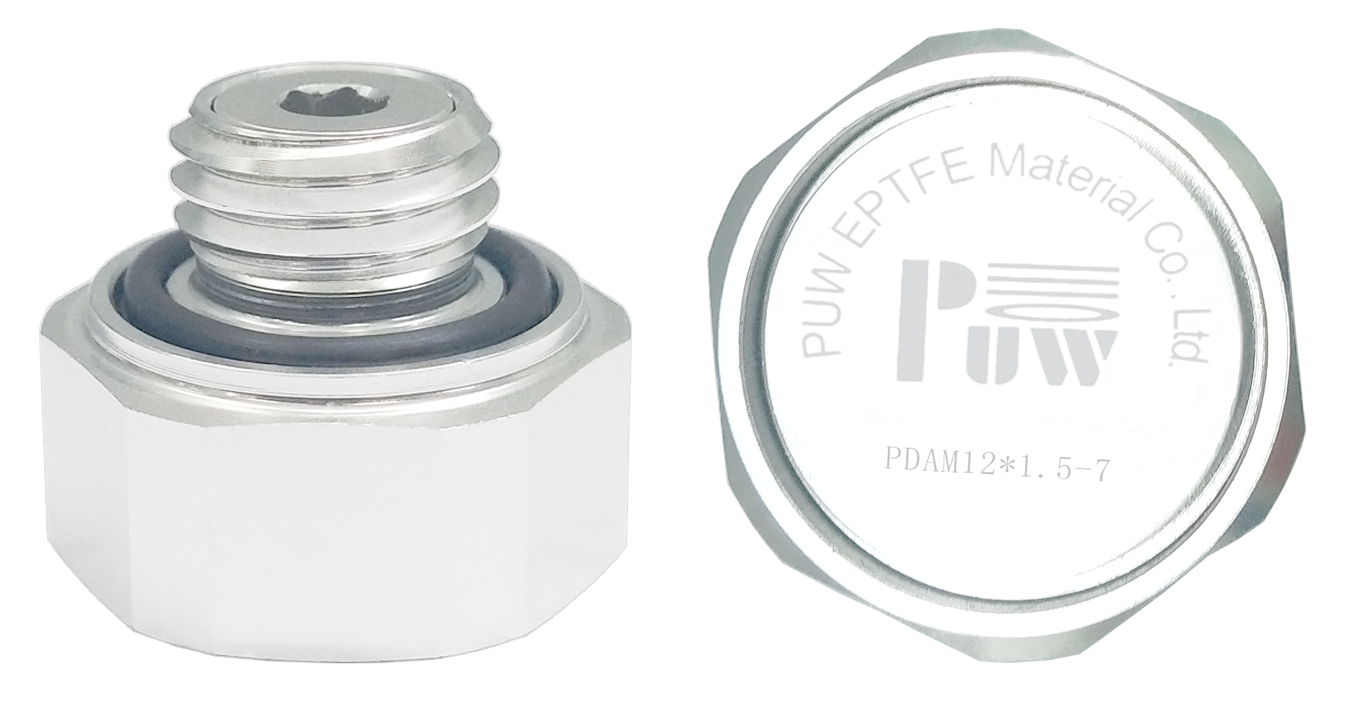

The One-Way Explosion-Proof Valves from PUW are specially designed for non-vacuum sealed cavities of new energy battery packs. These valves offer high hardness, crafted from aluminum with an anti-oxidation coating, ensuring excellent corrosion resistance. They boast a high protection rating of IP68 or above, with customization available. The valves are equipped with dual channels for both ventilation and pressure relief, ensuring efficient operation. With precise, customer-specific explosion-proof points and rapid gas tightness detection, these valves are easy to install. They are developed in-house, backed by multiple patents and certifications like ISO and IATF16949. Manufactured to international standards, they are available in various styles and can be customized to meet specific needs.

| Product model | PD16A4K-51X |

|

|

| Product type | Waterproof, breathable and explosion-proof valves | Body Material | Aluminum alloy |

| Valve installation type | Unidirectional explosion-proof valve (without waterproof and breathable membrane) | Ingress protection | IP68/6K9K |

| Air permeability ML/min@1.5kPa | / | kPa Turning pressure kPa | 12~19 |

| Air permeability ML/min@2.5kPa | / | Installation: | 4-hole external mounting |

| Fully open exhaust area of the spool (mm²) | 650 |

|

|

Key Features

Efficient Explosion Protection

Designed with advanced technology, One-Way Explosion-Proof Valves offer superior Explosion Vent Valve functionality, quickly relieving overpressure during an explosion to protect equipment and minimize damage.

Excellent Sealing and Flame Arresting

Incorporating Flame Arrestor Valve technology, these valves not only release pressure but also prevent flame propagation, ensuring the safety of the industrial environment.

Corrosion and High-Temperature Resistance

Constructed with premium corrosion-resistant materials, the valves are suitable for harsh conditions in Chemical Industry Explosion Valves and Dust Explosion Valves, withstanding high temperatures, pressures, and corrosive media.

Versatile for Various Industrial Applications

Whether Pneumatic Explosion Valves, Industrial Explosion Protection Valves, or Safety Vent Valves, these products meet diverse operational requirements and enhance system safety levels.

Easy Installation and Maintenance

Compact design allows for flexible installation in existing systems, with minimal maintenance requirements to reduce operational costs.

Typical Applications

1.Explosion protection for hazardous gases and dust in chemical and pharmaceutical industries

2.Pressure safety control in food processing plants

3.Pressure relief systems in oil and gas sectors

4.Explosion protection in power generation and machinery

5.Explosion venting and pressure balancing in ventilation and storage tanks

1.Compliance with international safety standards for equipment and personnel protection

2.Precise pressure control for improved system reliability

3.Multiple sizes and customization options for specialized industrial needs

4.Durable design that reduces replacement frequency and maintenance costs

1. What Is a One-Way Explosion-Proof Valve?

It is a safety valve designed to release excess pressure during an explosion, preventing damage to equipment and ensuring personnel safety by allowing gases or flames to vent in one direction only.

2. How Does the Valve Prevent Flame Propagation?

These valves incorporate flame arrestor technology that stops flames from traveling back into the protected enclosure while allowing pressure relief.

3. What Industries Use One-Way Explosion-Proof Valves?

They are widely used in chemical, pharmaceutical, food processing, oil and gas, power generation, and any industry dealing with combustible dust or gases.

4. Can These Valves Be Customized?

Yes, we offer customization options for valve size, pressure ratings, materials, and connection types to meet specific industrial requirements.

5. What Materials Are Used in These Valves?

Typically, corrosion-resistant metals and heat-resistant alloys are used to ensure durability under harsh conditions.

6. How Often Should These Valves Be Inspected or Maintained?

Regular inspection is recommended, typically every 6 to 12 months, depending on the operating environment and industry standards, to ensure reliable performance.