PUW is a leading Explosion-Proof Valve Manufacturer specializing in high-precision safety solutions for new energy vehicles (NEVs) and battery systems. Our Unidirectional Explosion-Proof Valves are engineered to maintain pressure balance and provide rapid relief in non-vacuum sealed cavities of battery packs, ensuring both performance and safety in harsh environments.

The PD12ALM20*1.5-15 model is made from high-grade aluminum with anti-oxidation coating, offering excellent corrosion resistance and a protection rating of up to IP68. Designed with a dual-channel system for ventilation and pressure release, our valves efficiently manage gas while providing precise and repeatable activation under predefined pressure thresholds.

Product Description & Application Value

A Unidirectional Explosion-Proof Valve, also known as a One-Way Explosion-Proof Valve or Explosion-Proof Vent Valve, is critical for controlling overpressure events in lithium battery packs, EV battery modules, and industrial energy storage systems. By allowing controlled venting in a single direction, these valves prevent structural damage, reverse flow, and potential explosions.

Our EV Battery Explosion-Proof Valve solutions are widely applied in:

Battery Pack Explosion-Proof Valve systems for NEVs

Pressure Relief Valve for Battery enclosures

Gas Release Valve for EV Batteries

Industrial safety systems with high-pressure risk

The valves are also compatible with dust collectors, chemical storage tanks, and pharmaceutical vessels, ensuring personnel and equipment protection in various industrial scenarios.

Key Features (Safety, Efficiency, Durability)

1. One-Way Venting Design

Releases pressure only in the designated direction

Prevents back-pressure and secondary explosions

Ensures safe venting in enclosed systems

2. High Venting Efficiency

3. Durable Construction

Made of aluminum alloy or stainless steel

Explosion-proof composite structures for extreme conditions

Optional flame arrestors for additional safety in volatile environments

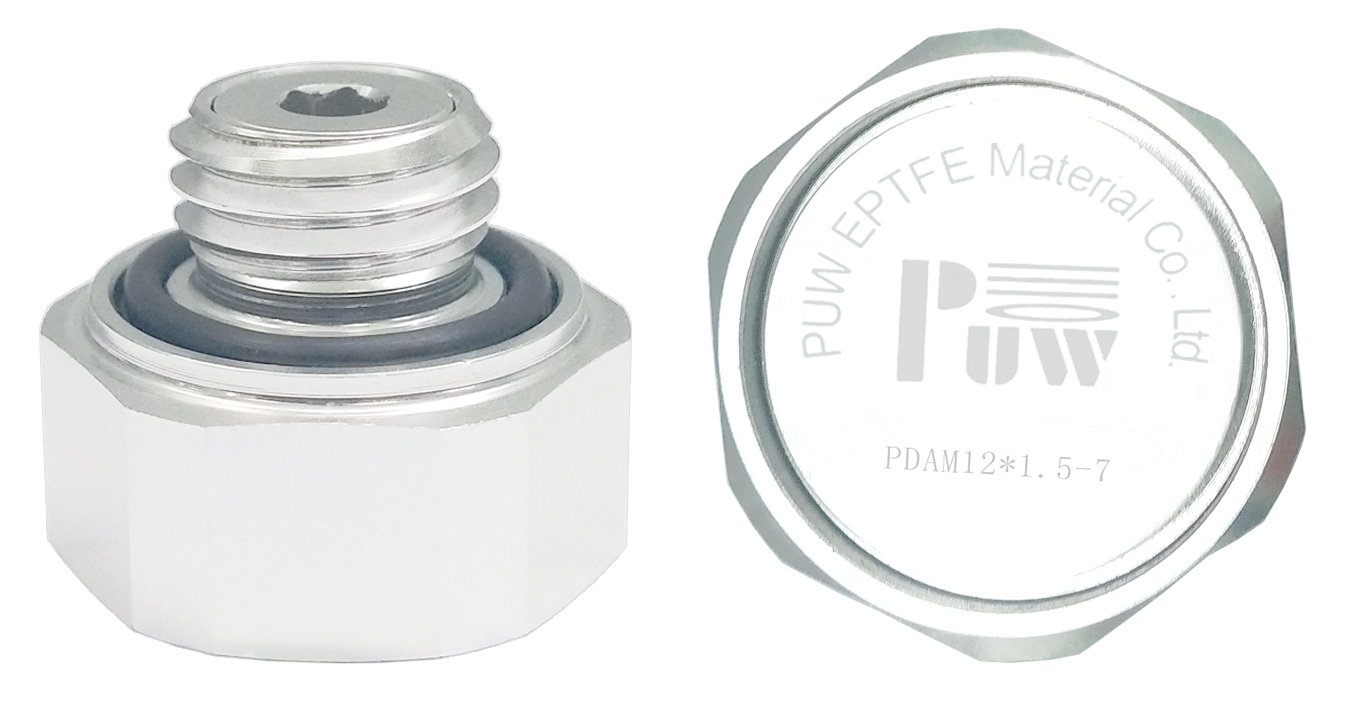

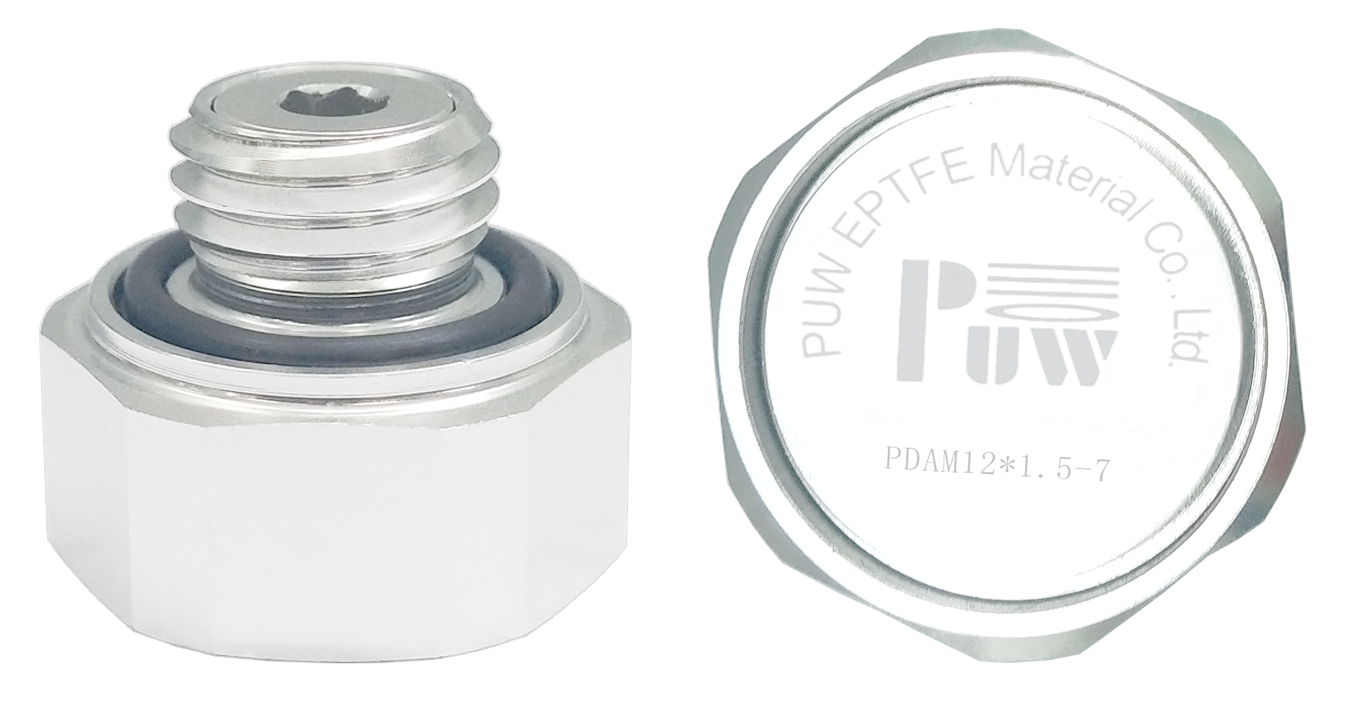

4. Compact & Easy Installation

Threaded installation for stable mounting

Ideal for battery enclosures, pressure vessels, and filtration systems

Supports OEM Battery Vent Valve customization

| Product model | PD12ALM20*1.5-15 |

|

|

| Product type | Waterproof, breathable and explosion-proof valves | Body Material | Aluminum alloy |

| Valve installation type | Unidirectional explosion-proof valve (without waterproof and breathable membrane) | Ingress protection | IP68/6K9K |

| Air permeability ML/min@1.5kPa | / | kPa Turning pressure kPa | 9~15 |

| Air permeability ML/min@2.5kPa | / | Installation: | threaded installation |

| Fully open exhaust area of the spool (mm²) | 105 |

|

|

Industrial Applications

EV Battery Packs & NEV Safety Systems – Protects lithium-ion modules from overpressure and thermal runaway

Dust Collector Explosion Vents – Ensures safe venting in industrial filters

Chemical & Petrochemical Storage – Prevents container rupture during explosive reactions

Pharmaceutical & Food Processing – Safe pressure relief in cleanroom and silos

High-Pressure Industrial Systems – Controls gas release efficiently and reliably

Why Choose PUW as Your Explosion-Proof Valve Supplier?

Trusted Explosion-Proof Valve Manufacturer with global export experience

Custom Explosion-Proof Valve and OEM Battery Vent Valve options available

Strict quality control and adherence to ATEX, EN14491/EN14994, and NFPA68 standards

Innovative in-house R&D with multiple patents and certifications (ISO, IATF16949)

Fast delivery and competitive pricing for Industrial Explosion-Proof Valves

FAQ

1. What is a Unidirectional Explosion-Proof Valve?

It is a One-Way Explosion-Proof Valve that allows pressure to vent in a single direction, protecting personnel and equipment during explosive events in batteries, dust collectors, or chemical systems.

2. How does it differ from a bidirectional valve?

Unlike bidirectional valves, our unidirectional valves prevent reverse flow and secondary explosions, making them safer for enclosed systems.

3. What materials are used?

Aluminum alloy, stainless steel, and explosion-proof composites. Optional ePTFE membranes provide waterproof and breathable capabilities.

4. What is the standard opening pressure?

Customizable from 0.05 bar to 1.5 bar, depending on system requirements.

5. Where is it commonly used?

Battery pack enclosures, EV/NEV systems, dust explosion protection, chemical storage, pharmaceutical vessels, and industrial high-pressure systems.

6. Can I request a custom valve design?

Yes. PUW supports full customization including shape, size, pressure rating, material, installation method, and flame arrestors.

7. Are your valves compliant with international safety standards?

Yes. All valves comply with ATEX, EN14491, EN14994, and NFPA68 standards. Third-party testing reports are available.

8. Do you offer bulk supply?

Absolutely. PUW provides bulk supply, wholesale pricing, and global shipping for standard and custom models.