Waterproof Breathable Membrane

Model: PUW280

Waterproof breathable membranes combine the essential properties of waterproofing and breathability, making them indispensable across diverse industries. Their ability to maintain comfort and protection, even in harsh conditions, ensures they remain a leading choice for modern applications.

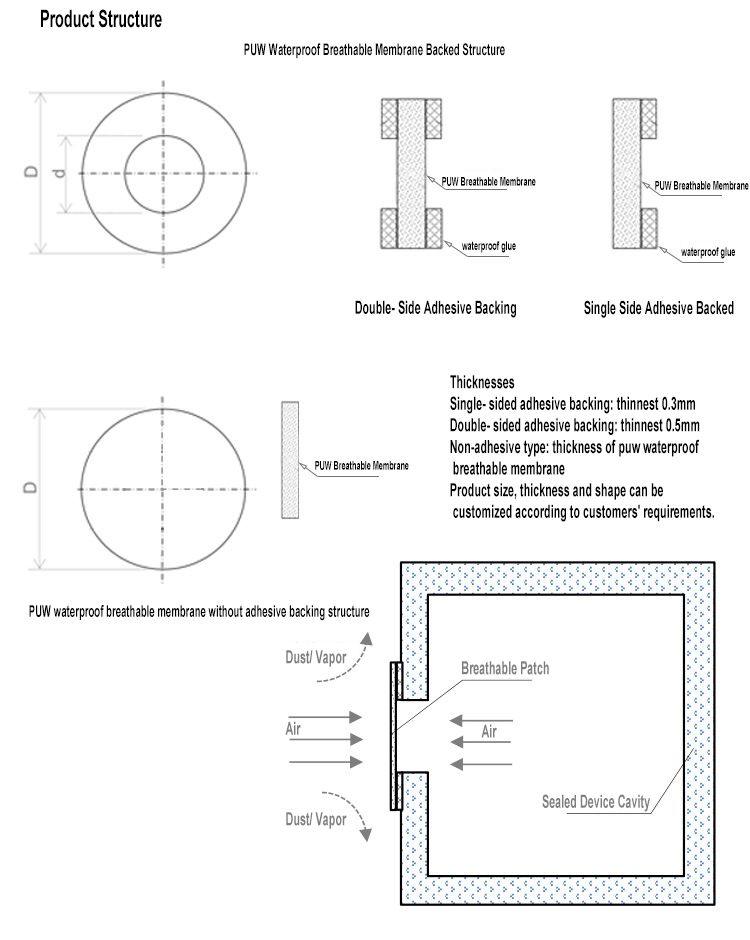

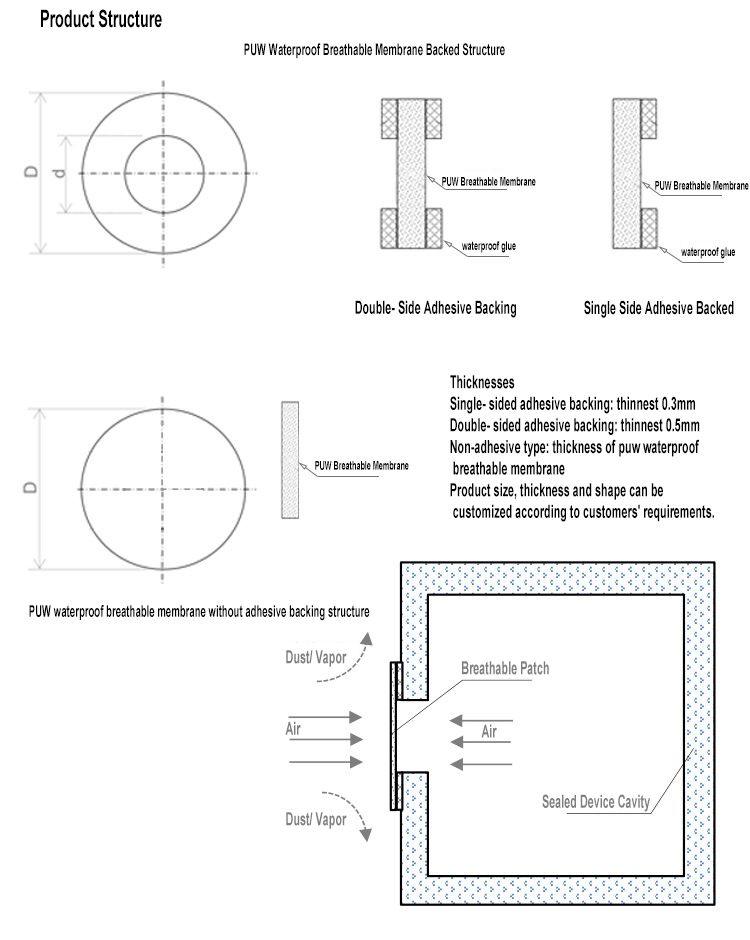

Product Details

The Waterproof breathable membrane is an advanced material designed to provide exceptional waterproofing while allowing air and moisture vapor to pass through. Its innovative structure ensures high performance in maintaining breathability and water resistance simultaneously, making it ideal for applications across construction, apparel, medical, and industrial sectors.

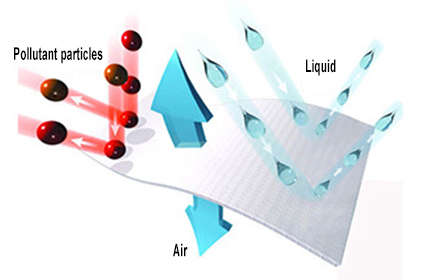

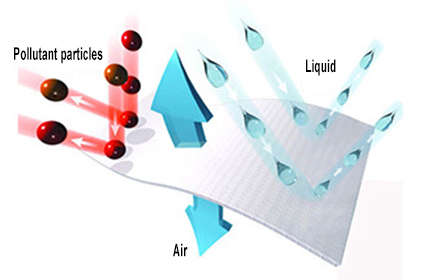

Product Working P rinciple

rinciple

The working principle of the waterproof and breathable membrane skillfully combines the characteristics of water molecules and the law of capillary movement. In the gaseous state, the particles of water vapor are very small and can smoothly pass through the tiny pores on the membrane, thus realizing air permeability. When the water vapor condenses into water droplets, the particles become larger, and due to the effect of the surface tension of the water droplets (water molecules pulling each other and bonding tightly), the water molecules are unable to detach from the droplets and pass through the pores, which prevents water from penetrating. It is this design that gives the breathable membrane its unique function of being both breathable and waterproof.

Product Performance Characteristics

Waterproof Performance: Effectively blocks rainwater, snow, and external moisture from penetrating surfaces.

Breathable Design: Allows internal moisture vapor to escape, preventing condensation and mold growth.

Durable & Tear-Resistant: High tensile strength ensures long-lasting protection under harsh conditions.

Lightweight & Flexible: Easy to handle and install on various surfaces without compromising structure.

UV and Weather Resistant: Maintains performance under sunlight, wind, and temperature fluctuations.

Key Technical Parameters

| Performance Indicator | Typical Value |

|---|

| Thickness | 0.10mm~0.15mm |

| Breathability | ≥2000g/m²·24h (ASTM E96 Test) |

| Waterproofing Performance | ≥10,000mmH₂O (ISO 811 Test) |

| Tensile Strength | ≥15MPa |

| Elongation at Break | ≥150% |

| Chemical Resistance | Resistant to acids, alkalis, and oil stains |

| Service Life | 15~20 years (in construction applications) |

| Operating Temperature | -40°C to +120°C |

| Fire Resistance (Optional) | Flame retardancy up to B1 or higher (as required) |

Applications

Construction Industry: Roof underlays, wall wraps, and foundation barriers to protect buildings from water ingress.

Outdoor Apparel: Jackets, shoes, and gloves requiring waterproof yet breathable performance.

Sports & Outdoor Gear: Tents, backpacks, and sleeping bags for enhanced comfort and protection.

Industrial Equipment: Protective covers, membranes, and liners in machinery or storage areas.

Marine Applications: Boat covers, decks, or other water-exposed structures.

Advantages for End Users

Enhanced Comfort & Safety: Reduces moisture accumulation while keeping surfaces dry.

Energy Efficiency: Breathable membranes help maintain insulation performance in buildings.

Long-Term Durability: Resistant to tearing, UV damage, and extreme weather conditions.

Versatile Usage: Suitable for multiple industries including construction, apparel, and outdoor equipment.

Easy Installation: Lightweight and flexible material simplifies application, saving time and labor.

FAQ

Q1: How does a waterproof breathable membrane work?

A: It blocks external water while allowing moisture vapor from inside to escape, preventing condensation and maintaining dryness.

Q2: Can it be used for both walls and roofs?

A: Yes, it is suitable for multiple construction applications including walls, roofs, and foundations.

Q3: Is it UV resistant?

A: Most membranes are treated to resist UV exposure, maintaining performance over time.

Q4: Can it be used in outdoor gear like jackets or tents?

A: Absolutely. Its waterproof yet breathable design is ideal for apparel and outdoor equipment.

Q5: How long does it last once installed?

A: Depending on environmental conditions, a quality membrane can last 10–20 years in construction applications.

rinciple

rinciple